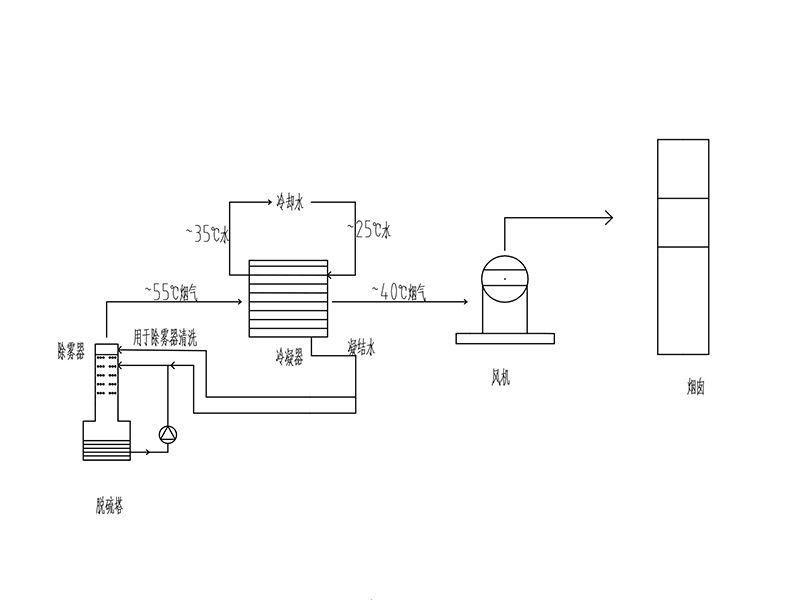

Recovery of flue gas waste heat after desulfurizing tower for water-saving system of flue gas deep condensation

Product features:

(1) The water-saving device of flue gas deep condensation is made of high thermal conductivity tube material made from low-dimensional carbon-based composite material, which has good thermal conductivity and corrosion resistance.

(2) It can carry out deep treatment on various pollutants of low-concentration in the flue gas after the wet desulphurization.

(3) It can recycle condensate water, which is utilized in a gradient manner and can be used for spray, cleaning and recycling after treatment.

(4) Investment cost is low, and the running cost is low.

Product description:

The flue gas after desulfurization is saturated wet flue gas with a temperature of about 50 ℃ and a high moisture content of about 12% ~ 18%, and there is a large amount of sensible heat and latent heat of vaporization in the saturated wet flue gas, so if the flue gas is discharged directly, put will waste a lot of water resources, aggravate the corrosion of the chimney, and also produces white smog rain. Flue gas deep condensation water-saving device of this kind adopts a high thermal conductivity tube material made from low-dimensional carbon-based composite material, so that the corrosion problem can be effectively solved; and meanwhile, a large amount of water in the flue gas can be condensed and separated out by the device, so that the waste of water resources is reduced. It can be used for spraying and demister cleaning, part of the condensation water is collected by the liquid collector, and the collected condensate water can be reused by the power plant after conditioning, thus realizing water saving.