Multi-effect evaporator

Technical parameters of multi-effect evaporator:

1.Evaporation capacity of the product: 5 t/h-60 t/h

2. Evaporation temperature: 40 ℃ -100 ℃

3. Power consumption for evaporation of every ton of water : 8-15 kw

4.Feed concentration: no requirement

5. Solid content of discharged material: it can be directly evaporated to crystallization.

6. Heat exchange components: can be designed as evaporators of plate type, tube type and etc

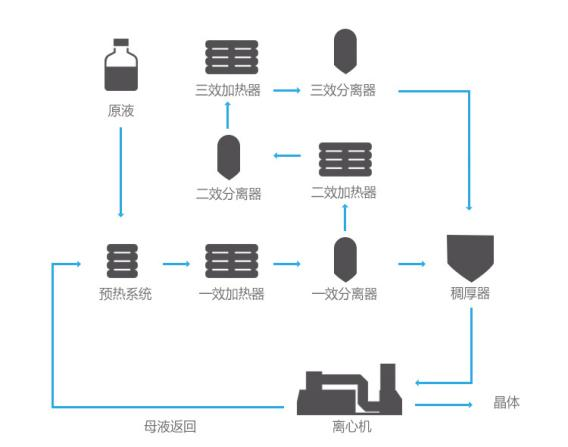

Working principle of multi-effect evaporator:

The principle of multi-effect evaporator is to use fresh steam to drive the first effect to produce evaporation, and then use the secondary steam produced by the first effect to drive the next effect to evaporate, so as to achieve the purpose of energy saving. In order to reduce the consumption of the primary steam, the secondary steam generated in the production is introduced into the second evaporator to be used as heating steam, and the secondary steam generated by the second evaporator can also be introduced into the third evaporator to be used as heating steam, and each evaporator is called one effect, and so on. In this way, several evaporators are operated in series to form a multi-effect evaporator.

Multi-effect evaporators have been developed from primitive evaporation kettles to single-effect, double-effect, three-effect, four-effect or evaporators with more effects, the aim of all of them is to gradually reduce energy consumption.

Multi-effect evaporator can adopt forced circulation, natural circulation, falling film, rising film, plate type evaporator and other forms, and can also adopt a variety of combinations to optimize the technological process.

|  |  |